Last Updated on May 14, 2021

Single overhead and dual overhead camshafts have been a part of automotive, marine, motorcycle and aircraft engines since the early 20th century.

Some of the first cars with a single overhead camshaft (SOHC) were the British designed 1902 Maudsley and the American 1903 Marr Autocar.

Dual overhead camshafts (DOHC) appeared in a French Peugeot which won the 1912 French Grand Prix.

Overhead cam engines graced a number of World War I military aircraft. Many of these engine designs used shafts to drive the cams. Today’s common timing chain driven camshafts followed in popular automobiles of the 1920s.

DOHC engines grew in popularity for many automobile makes following World War II, notably Fiat and Alfa Romeo. Today single and dual overhead cam designs proliferate in our domestic and foreign built cars. Keep reading to see how SOHC and DOHC engines compare to each other as well as the cam-in-block engine.

See Also: Straight Cut Gears vs Helical Gears

The Purpose of the Camshaft

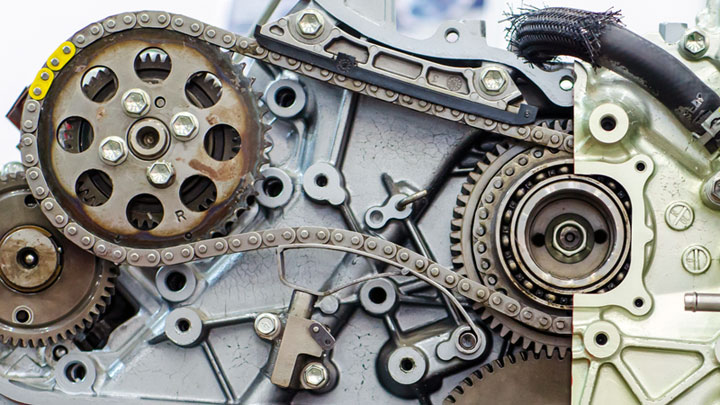

Today’s automotive piston engines utilize one or more camshafts to operate the intake and exhaust valves. The camshaft is driven by the engine crankshaft using a chain or belt that coordinates the timing of the intake and exhaust valves.

These valves admit air and fuel to the combustion chambers and enable the burnt mixture to be discharged to the exhaust system.

What is a SOHC Engine?

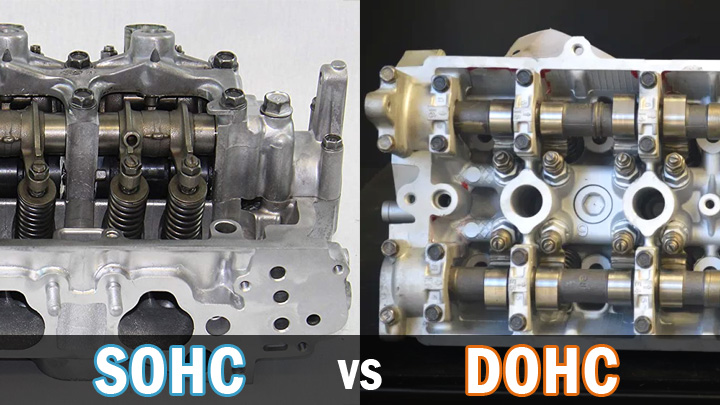

First, both SOHC and DOHC engine designs are overhead valve configurations.

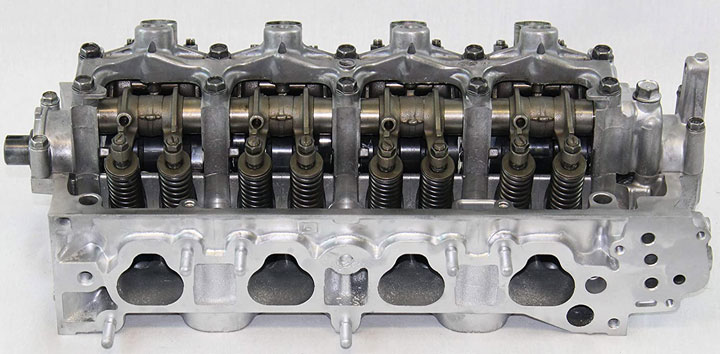

A single overhead camshaft engine employs one camshaft located above each bank of cylinders. For a “V” design engine such as a V6 or V8, there would be two such camshafts, one above each cylinder bank. The camshaft would be driven by either a chain or a toothed timing belt.

At the choice of the engine designer, any number of methods could be used to operate the valves from this single camshaft. If, for example, all the valves were aligned parallel to the length of the cylinder head, the cam could operate all of them directly. For other valve arrangements, rocker arms or occasionally very short pushrods could be used.

SOHC Advantages

The SOHC design offers several advantages over the cam-in-block design:

The SOHC design offers several advantages over the cam-in-block design:

- Valves can be positioned for best combustion chamber design. Multiple valves can be employed; as many as five per combustion chamber are possible. Dual spark plugs can be utilized as well. These improvements can improve fuel-air flow and combustion capabilities offering increased power and better fuel economy.

- Passageways through the engine block and cylinder head for pushrods are not required. Both areas can thus employ additional (or larger) coolant passages improving cooling efficiency. Upgraded cooling especially in the cylinder head areas can enable higher compression ratios. This benefits both power output and fuel economy.

- The mechanism operated by the camshaft to open the valves can be both simpler and lighter. This reduces the opportunity for valve float making much higher engine speeds possible. Higher RPMs in general enhance power output.

- Access to all components of the valve system, especially the camshaft, is simpler. Repairs to this critical area of the engine would then be less costly.

SOHC Disadvantages

There are some disadvantages to the SOHC engines when compared to the cam-in-block designs as well as to the DOHC designs:

- Engine complexity is increased. This adds to design and manufacturing cost. There may also be an overall increase in engine weight compared to cam-in-block designs. Camshaft drives using a chain or a belt can introduce reliability and maintenance considerations not common to cam-in-block engines.

- The engine can become taller and require increased hood height for clearance. Due to the engine size increase, weight may be increase also.

- Variable valve timing is largely restricted to timing changes for both intake and exhaust valves simultaneously. This is the same timing problem that exists for cam-in-block engines.

See Also: Spoon Engine Facts

What is a DOHC Engine?

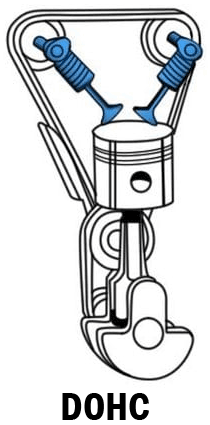

A dual overhead camshaft engine will have two camshafts located above each bank of cylinders. A “V” design engine such as a V6 or V8 would have a total of four camshafts. As with the SOHC engine design, the DOHC would utilize either timing chains or a toothed belt to drive the camshafts.

In most cases with a DOHC (or twin cam) engine each cam would directly operate its associated valves.

DOHC Advantages

DOHC engines share the same advantages of the SOHC designs. These include:

DOHC engines share the same advantages of the SOHC designs. These include:

- Valves can be positioned for best combustion chamber configuration. Power and fuel economy can benefit by optimizing the valve arrangement.

- Engine block and cylinder head cooling efficiency is enhanced with DOHC designs. Increased compression ratios offer increased power and fuel efficiency.

- DOHC designs offer the most direct operation of the valves. Peak engine RPMs of 8,500 or higher are possible for street automobiles. Racing vehicles can attain even higher engine speeds with advanced DOHC systems.

- Maintenance accessibility to the camshafts and lifters is easier. This can help reduce overall maintenance and repair costs.

- DOHC engines make possible the best of VVT benefits. Variable valve timing can operate independently for each camshaft providing optimum valve timing for both the intake and exhaust valves.

DOHC Disadvantages

As with SOHC engines, DOHC designs share the same basic disadvantages.

- Engine complexity and weight are increased compared to cam-in-block designs. Design and manufacturing costs are higher as well. Compared to SOHC designs, DOHC engines have a more complex chain or belt drive system. This decreases overall reliability and adds to maintenance expense.

- As with SOHC designs, DOHC engine height is increased and overall weight also tends to be higher.

What is a Cam-in-Block Engine?

The majority of the engines powering American cars built just after World War II were cam-in-block designs. These utilized a single camshaft located inside the engine block. This camshaft directly actuated the valves for several popular flathead engines.

For higher performance overhead valve (OHV) engines (engines with valves located above the combustion chambers), the camshaft operated each valve via a system of pushrods and levers called rocker arms.

Cam-in-Block Advantages

The primary advantages of the cam-in-block valve systems are these:

- Such systems were simple and economical to design and manufacture.

- They proved to be very reliable.

- Cam-in-block engines have relatively low overall height. This enables lower hood profiles which can be a boon to sleek auto body designs.

Cam-in-Block Disadvantages

Cam-in-block designs have certain disadvantages especially for OHV engines:

- Space allocations for the pushrods through the engine block and for the rocker arms on the top of the cylinder head can adversely dictate or crowd the location of other components.

- Pushrod and rocker arm geometry may force inefficient shape and size of the cylinder head combustion chambers.

- The mass (or weight) of the mechanism between the camshaft and each valve introduces inertial effects that limit the speed of operation of the valves. At very high engine speeds, e.g., above 7,000 revolutions per minute (RPM), the valves may fail to completely close. This is called valve float which will always limit engine power output.

- The pushrods require passageways up through the engine block and cylinder heads. Such passageways may constrict the size of cooling zones in the engine block and cylinder heads, tending to degrade cooling efficiency.

- Independent variable valve timing (VVT) which can boost performance and fuel economy would be difficult to provide for both intake and exhaust valves.

Some of today’s very high performance engines remain cam-in-block designs. These designs can include a form of variable valve timing. However, cam timing variations would be simultaneous for both the intake and exhaust valves since these engines have only one camshaft.

How Can You Tell If You Have SOHC or DOHC?

In general, you can simply open the hood of your car and examine the top of the engine. A narrow but tall engine top with a distinct hump at the front for the cam drive sprocket will generally indicate that a SOHC is hidden beneath.

A wide engine and/or two-humped top will give away the presence of a DOHC setup. If in doubt, an online search for the make, model, year and engine size for your car should provide clarification in this respect.

Can You Change SOHC to DOHC?

To make such a change would, in general, be extremely costly. However, certain make and model cars have similar engine choices in both SOHC and DOHC configurations. Some Honda models fit this mold.

For specific models, an SOHC cylinder head can be swapped for a DOHC head. And with appropriate engine control unit (ECU) reprogramming and auxiliary engine systems changes (plus good DIY skills) such a transition is definitely possible..

This was very informative but easy to understand. It has just helped me with a buying decision for a 2016 subaru crosstrek, so I appreciate the timing of seeing this.