Last Updated on January 25, 2022

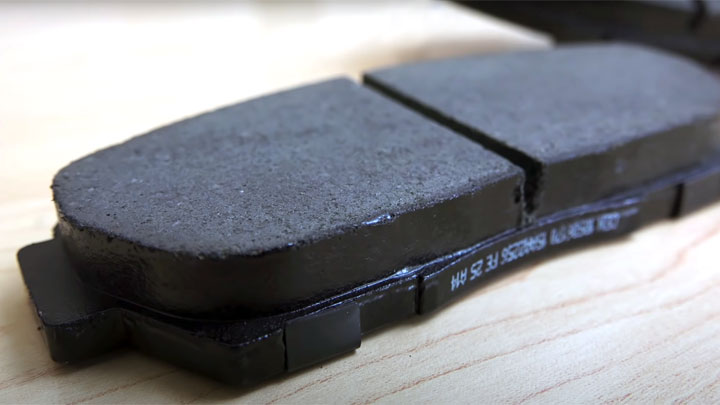

Over a period of years, a vehicle’s brake pads slowly wear out, eventually requiring replacement. This leads an untold number of consumers every year to venture to their nearest auto parts store, in search of replacement brake pads.

While many would think that the matter of choosing a set of brake pads for their vehicle would be rather straightforward, a number of product options do exist.

Brake pads come in several different material compositions, all of which offer their own advantages and disadvantages, as well as functional applications.

Read on to learn more about the different types of brake pads that are currently available and which pad material is best for your particular driving style.

Related: How Long Do Brake Pads Last?

Brake Pad Materials

Brake pads can best be described in three individual subsets; semi-metallic, ceramic, and organic. Each of these three subsets carries their own distinct properties, providing significant value for the individual application for which they are intended.

Semi-Metallic

Semi-metallic brake pads are generally considered to be superior in absolute stopping power, to any other type of brake pad currently available. As their name would suggest, semi-metallic brake pads utilize a significant amount of metal within their composition.

Though the exact amount varies by manufacturer, metallic brake pads generally consist of 35%-65% metal. The exact metals used within semi-metallic brake pad construction also differ.

However, some of the most common materials include copper, steel, and iron. Semi-metallic brake pads also utilize fillers, friction modifiers, and graphite lubricants within their construction.

While semi-metallic brake pads are known for their unparalleled stopping ability, pads of this nature are prone to producing brake noise, as well as a notable amount of brake dust. Semi-metallic pads also tend to be harsher on brake rotors, than both ceramic and organic pads.

Pros:

- Unparalleled stopping ability

- Excellent high-heat performance

- Superior cold-bite

- Low rate of compressibility

- Highly resistant to brake fade

Cons:

- Noisier operation

- Higher production of brake dust

- Harder on brake rotors

- More expensive than organic alternatives

Read Also: Minimum (and Recommended) Brake Pad Thickness

Organic

Organic brake pads have been a mainstay of automotive brake production for numerous decades. Pads of this nature were initially designed as a large scale replacement for asbestos-based brake pads, which were phased out due to environmental and health-related concerns.

A number of chemicals and substances are utilized in the production of organic brake pads. Some of the most common of these materials include Kevlar, rubber, fiber, and carbon, which are bound together in a durable resin.

Today, more than 70-percent of new vehicles come equipped with organic brake pads. This composition of brake pad also tends to be among the most economical to purchase. This is largely thanks to the relative abundance of the materials used within their manufacturing process.

Pros:

- Excellent daily driving performance

- Inherently quiet in operation

- Produces less dust than semi-metallic alternatives

- Offers sufficient cold-bite

- Economically priced

Cons:

- Quicker wear than alternative pad types

- Relatively limited in operational temperature range

- Higher compressibility rate than other pad types

- Not suited to demanding driving circumstances

Ceramic

Ceramic brake pads are relatively new, in relation to brakes of semi-metallic or organic composition. This style of brake pad was first introduced in the 1980s, and has been steadily increasing in popularity ever since.

Pads of this composition are known for their absence of operational noise, and general minimization of brake dust production. Ceramic brake pads also tend to be easier on rotors, than pads of a semi-metallic build, yet somewhat more abrasive than organic pads.

While ceramic brake pads carry a long list of advantages, they also typically command a higher sales price than semi-metallic or organic brake pads. Motorists can often expect to pay nearly double the price of organic pads, for a quality set of ceramic brake pads.

Pros:

- Provide excellent stopping power

- Produce very little noise

- Not prone to excess brake dust production

- Consistent in a wide range of conditions

Cons:

- Harsher on brake rotors than organic pads

- Not the best choice for extremely cold climates

- Not suited for racing or extreme-duty usage

- More expensive than alternative pad types

Brake Pad Comparison Chart

| Pad Type | Performance | Noise | Dust | Wear on Rotors | Price |

|---|---|---|---|---|---|

| Semi-Metallic | Very High | Moderate | Moderate | High | $$ |

| Organic | Moderate | Low | Low | Low | $ |

| Ceramic | High | Very Low | Very Low | Moderate | $$$ |

OEM vs Aftermarket

When brake pad replacement becomes necessary, it is quite common for motorists to question whether to select a set of direct OEM replacement pads, or a suitable aftermarket alternative. In the vast majority of cases, this decision comes down to a matter of personal preference and driving style.

OEM brake pads are selected for a particular vehicle by its manufacturer, in a bid to provide acceptable performance, while minimizing the production of noise and brake dust. However, pads of this nature are seldom selected for their longevity or capabilities under extreme circumstances.

On the other hand, the vast majority of aftermarket brake pads are engineered to provide superior stopping power, unparalleled responsiveness, and greater protection against brake fade. However, these pads also are prone to a higher degree of brake dust production and operational noise.

Additionally, aftermarket brake pads tend to be more abrasive, often causing rotors to wear more quickly than when using OEM pads.

See Also: 6 Causes of Uneven Brake Pad Wear

Best Type of Brake Pads

Each style of brake pad has its specific set of uses, to which it is best suited. By understanding the value of each type of brake pad, you are better able to make an informed buying decision.

Related: Best Brake Pads for Cars, Trucks, and SUVs

For Daily Driving: Organic Pads

When driving solely to work and back, or to the grocery, organic brake pads are typically the best available choice. These pads provide ample stopping power in the vast majority of scenarios, and operate largely in absence of brake dust and operational noise.

Organic brake pads can also be purchased at an economical price point, in comparison to ceramic or semi-metallic pads. In a daily driving scenario, many consumers are unlikely to notice much in the way of improved performance, with the use of more expensive semi-metallic pads.

Runner Up: Ceramic Pads – Alternatively, ceramic brake pads can also be used in a daily driving scenario, if motorists wish to extend pad life. This can be of benefit to those who commute long distances to work and back daily.

For Spirited Driving: Ceramic Pads

When one expects to encounter more demanding conditions along their daily route, ceramic brake pads often prove to be an excellent choice. Ceramic pads wear at a slower rate than organic pads, while offering excellent stopping capabilities.

Pads of this nature also tend to operate in relative absence of audible noise, and produce brake dust that rarely sticks to a wheel or becomes visually evident. This often makes ceramic pads a wise choice for those who travel winding country roads, where frequent braking is necessary.

Runner Up: Semi-Metallic Pads – If you commute through mountainous terrain, where you are forced to brake repetitively, semi-metallic brake pads are another excellent choice. Semi-metallic pads have a higher thermal threshold, allowing them to better cope with periods of demanding brake operation.

For Track Use: Semi-Metallic Pads

When hitting the track, there is really no substitute for the use of a quality set of semi-metallic brake pads. Semi-metallic pads offer excellent stopping power and provide superior cold-bite, as well as unsurpassed operational characteristics when faced with immense heat.

Semi-metallic brake pads also present a low threshold of compressibility, which provides a driver with the feeling of a firm, consistent brake pedal.

This level of consistency is highly appreciated by most when speeding around the track at a high rate of speed whether you’re taking part in your first autocross, track day, or a lap on the Nürburgring.

Runner Up: None – Neither organic, nor ceramic brake pads possess sufficient heat dissipation qualities to be suitable for track use. When heated to an extreme degree, both are prone to brake fade, which can ultimately become a safety issue.

You have three options when it comes to brake pads: ceramic, organic, and semi-metallic. Under normal driving conditions, semi-metallic brakes are regarded to have better gripping force than ceramic or organic brakes. These brakes are made of bronze, iron, and steel wool and are quite efficient in removing heat. Ceramic brakes, on the other hand, are the second most effective in terms of gripping. Ceramic brakes are quieter and emit less dust than other types of brakes. They also last longer. Lastly, Organic brake pads are made of many materials, including glass, rubber, and Kevlar. These pads have a modest advantage over the other two types in lower temperatures, but they may lose some braking force when driven at higher temperatures. They are also incredibly quiet, although they wear out more quickly than semi-metallic and ceramic brakes.